Manufacturers are increasingly overwhelmed by the technology requirements of today.

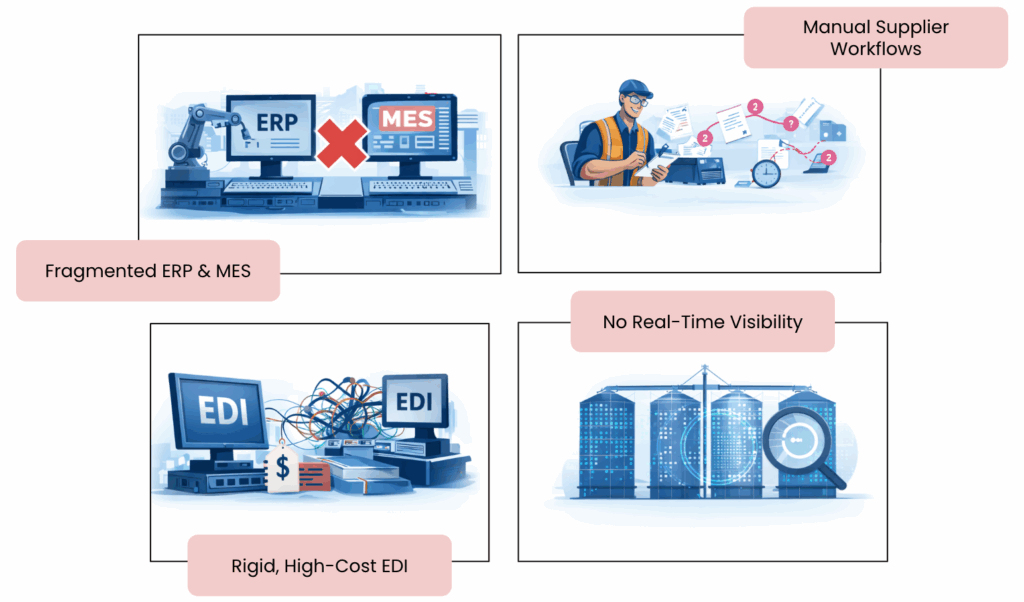

Enterprise resource planning (ERP) systems manage orders and finance. Manufacturing execution system (MES) platforms track production. Warehouse management system (WMS) tools handle inventory. Supplier portals, EDI networks, and customer service systems add even more layers. Each system works well on its own, yet together they often create friction rather than flow.

The result is delayed decisions, manual workarounds, limited visibility, and teams spending more time reconciling data than improving operations.

This is the manufacturing challenge of the decade: ensuring that digital capacity is not without digital cohesion.

Why Manufacturing Still Struggles With Integration

Manufacturing environments are uniquely complex. Many organizations operate a mix of legacy, on-premises systems alongside modern cloud applications. Over time, point-to-point integrations and manual processes pile up, creating fragile dependencies and operational blind spots.

When systems don’t communicate effectively:

- Production changes aren’t reflected in inventory fast enough

- Supply chain disruptions ripple through the organization unnoticed

- Employees rely on spreadsheets, emails, and manual approvals

- Leadership lacks real-time insight into performance

Research from McKinsey suggests that up to “87% of the hours spent on activities performed by workers in production occupations are automatable,” yet many organizations struggle to realize this potential, not because automation tools don’t exist, but because systems aren’t connected in a meaningful way.

Integration as a Strategic Capability, Not an IT Project

Modern manufacturers are starting to view integration as a core operational capability, rather than just a technical necessity.

This is where platforms like Workato play a critical role.

Rather than relying on brittle, custom-built integrations, Workato provides a cloud-native platform designed to orchestrate data, processes, and workflows across the entire manufacturing ecosystem.

At a practical level, this enables manufacturers to:

Break Down System Silos

Workato connects ERP, MES, WMS, supplier systems, EDI networks, and cloud applications into a unified operational fabric, reducing manual handoffs and improving data consistency.

Enable Real-Time Data Orchestration

Production, inventory, quality, and supply chain data can move and transform in real time, allowing teams to:

- Respond faster to operational changes

- Reduce errors caused by stale or duplicated data

- Improve forecasting and planning accuracy

Automate Intelligent, Event-Driven Workflows

Using advanced automation and agentic workflows, manufacturers can move beyond static rules to processes that:

- React automatically to production events

- Adjust workflows based on inventory or demand changes

- Escalate issues before they become disruptions

Real-World Impact: Lessons From Lucid Motors

The benefits of this approach are real.

Lucid Motors, a global electric vehicle manufacturer, faced many of the same challenges common across the industry: disconnected systems, slow internal processes, and limited visibility across operations.

Before implementing Workato, these gaps affected everything from employee onboarding to financing workflows and customer support. After establishing Workato as an integration backbone, Lucid Motors was able to:

- Reduce loan processing time from seven days to under five minutes

- Deploy over forty integrations across twelve countries

- Create a scalable, reliable foundation for global growth

The key takeaway is operational resilience and scalability. By establishing a unified integration backbone, Lucid Motors transformed disconnected systems into coordinated operations that could move at the speed of the business. Integration enabled faster decision-making, eliminated manual bottlenecks, and created the flexibility needed to support rapid global expansion. Lucid built a foundation that enables the addition of new workflows, regions, and business models without increasing complexity, thereby turning integration into a long-term competitive advantage rather than a short-term fix.

What Sets Modern Integration Platforms Apart

Not all integration approaches are created equal. Modern platforms differentiate themselves through:

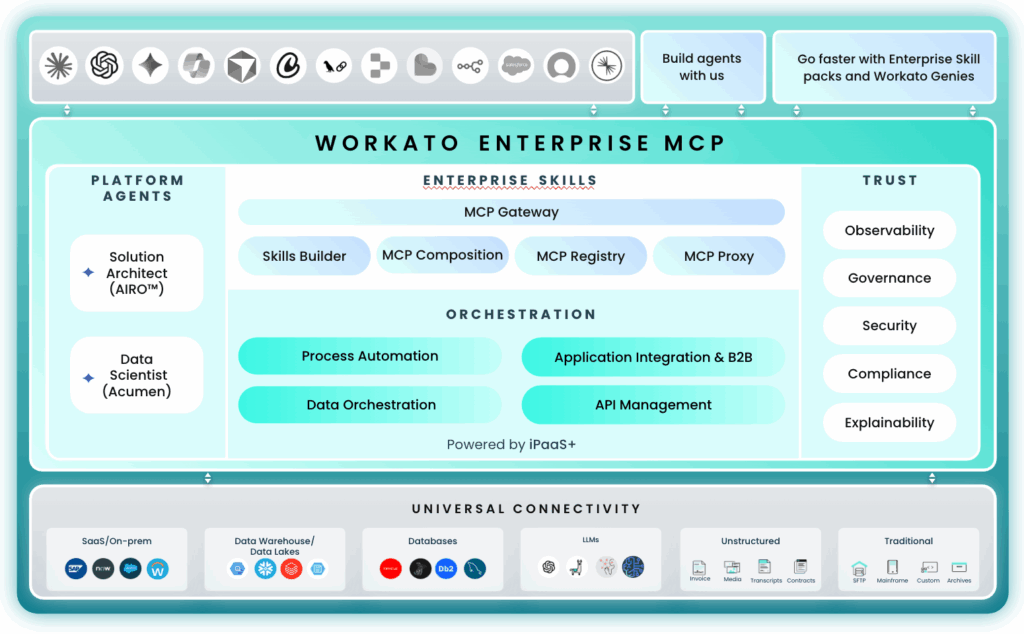

Universal Connectivity

Thousands of pre-built connectors support both legacy and cloud systems, reducing integration time and the need for long-term maintenance.

End-to-End Workflow Automation

From order management and production to logistics, suppliers, and customer service, workflows can span departments instead of stopping at system boundaries.

Enterprise-Grade Governance and Security

Centralized monitoring, role-based access, and scalable pricing allow organizations to expand automation without sacrificing control.

Modern integration platforms bring these capabilities together into a single, cohesive operational layer. Rather than treating connectivity, automation, and governance as separate initiatives, leading platforms unify them through a common orchestration backbone. This enables manufacturers to integrate systems of record, automate cross-functional workflows, and consistently govern data and processes at scale. The architecture below illustrates how modern platforms combine universal connectivity, end-to-end orchestration, and enterprise-grade trust into one integrated foundation.

The Future of Manufacturing Is Orchestrated

As manufacturing becomes increasingly global, digital, and data-driven, complexity will continue to rise. The organizations that lead will be those that can:

- Reduce technical debt instead of adding to it

- Respond quickly to disruption

- Free skilled employees from manual coordination work

- Turn real-time data into real-time action

Integration platforms like Workato are becoming foundational because they enable systems to work together effectively.

From Connected Systems to Connected Operations

The next phase of digital manufacturing is about making existing investments smarter, faster, and more adaptive.

By treating integration as a strategic capability and combining it with intelligent automation, manufacturers can move from fragmented operations to connected, resilient ecosystems.

The question is no longer whether manufacturing should modernize its integration strategy, but how quickly it can afford to do so.

Learn how manufacturers are using Workato to connect ERP, production, and supply chain systems into a unified, automated operation by exploring Workato’s manufacturing solutions page.