In the world of construction, the need to avert risk often blocks efforts to drive change and innovation. However, at the largest building company in Victoria, Australia, one trailblazing Digital Engineering Manager – Dominic Martens (henceforth Dom) – challenged this notion. With 16 years of experience designing highly complex and challenging builds, he ambitiously set out to give disjointed project teams in ICON, seamless access to critical data – the kind of data that is trapped in captive systems, requiring manual searches and tedious handoffs from those with specialised knowledge.

Today, by not just telling, but showing how a pair of two Digital Engineers can deliver 30 times more than peers in their industry, Dom has “unlocked a tidal wave” of requests across ICON, and even sparked the interest of their parent company, the multibillion dollar global powerhouse, Kajima. This is the story of how Dom teamed up with Workato to build a foundation for AI innovation, upheld by a keen focus on data quality and end-to-end orchestration.

Siloed data; wasted opportunity

Speaking at Automate Sydney 2024 and at Workato’s sold-out Work^AI launch, Dom opened up about the challenges faced by construction firms. Despite the explosion of construction technology, he cites how a staggering 96% of data created in construction is wasted and not reused. Engineers are redoing work. Why?

For one, engineers grapple with a fragmented technology stack where data lives in silos. Within ICON itself, Dom says he can easily name over 10 competing platforms that lock in data in their own systems, striving not to connect to competitors. For instance, Autodesk Construction Cloud (ACC) boasts the lion’s share of users in the construction management space, but does not integrate with up-and-coming players like Procore or age-old systems like Oracle Aconex.

Unfortunately, such turf-guarding behaviour also spills over to how project teams think about data. Without a governed way to integrate data, apps, APIs and business processes, engineers worry about how their intellectual property will be protected, and prefer not to share information. However, time is of essence in construction. This means that if project teams cannot seamlessly share critical data, such as the cost of concrete, which could change within a span of two weeks, a big portion of the project cost could be misestimated, resulting in delays and potential disputes.

This was only one part of the problem for Dom and his team. Although construction technologies come with powerful features, Dom calls out another elephant in the room. Why do engineers still need to spend so much time manually navigating through cumbersome work processes? Dom goes on to describe his own experience with ACC.

ICON ultimately chose ACC as their construction management software because it is positioned as having the most integrations and connectivity, to keep people in sync. However, once Dom discovered that ACC could not connect to Aconex without a third party platform, he drilled deeper to find out what could. After all, ICON was already paying the price for getting data in order. One graduate was spending all day everyday, manually copying over PDF drawings – sometimes 5000 PDFs at a time – from Aconex to ACC.

Speed, governance & innovation

What Dom learnt surprised him. Under the hood, all of ACC’s integration capabilities were being powered by Workato. What possibilities could be unlocked if ICON used Workato directly? This spurred Dom to take Workato for a spin.

Within 2 weeks of getting his hands on the platform, Dom built a chatbot that queries the dRofus database. Like many other platforms ICON was using, dRofus presented data in an antiquated format that Dom describes as being too “painful” to work on directly. He gave himself 30 minutes to experiment with Workato. The result? A chatbot that exports the required data from dRofus, advising on who is working on a construction project, and who was the last to access a database. Dom knew he had stumbled upon a game-changer. It was time to tackle the root problem.

1.) Effortlessly sync drawings from Oracle Aconex to ACC

ICON first used Workato to connect ACC and Oracle Aconex, so that no one needs to lift a finger when they require up-to-date access to drawings – Intercede Solutions built this with them. Several other possibilities unfolded from there. Dom puts it this way:

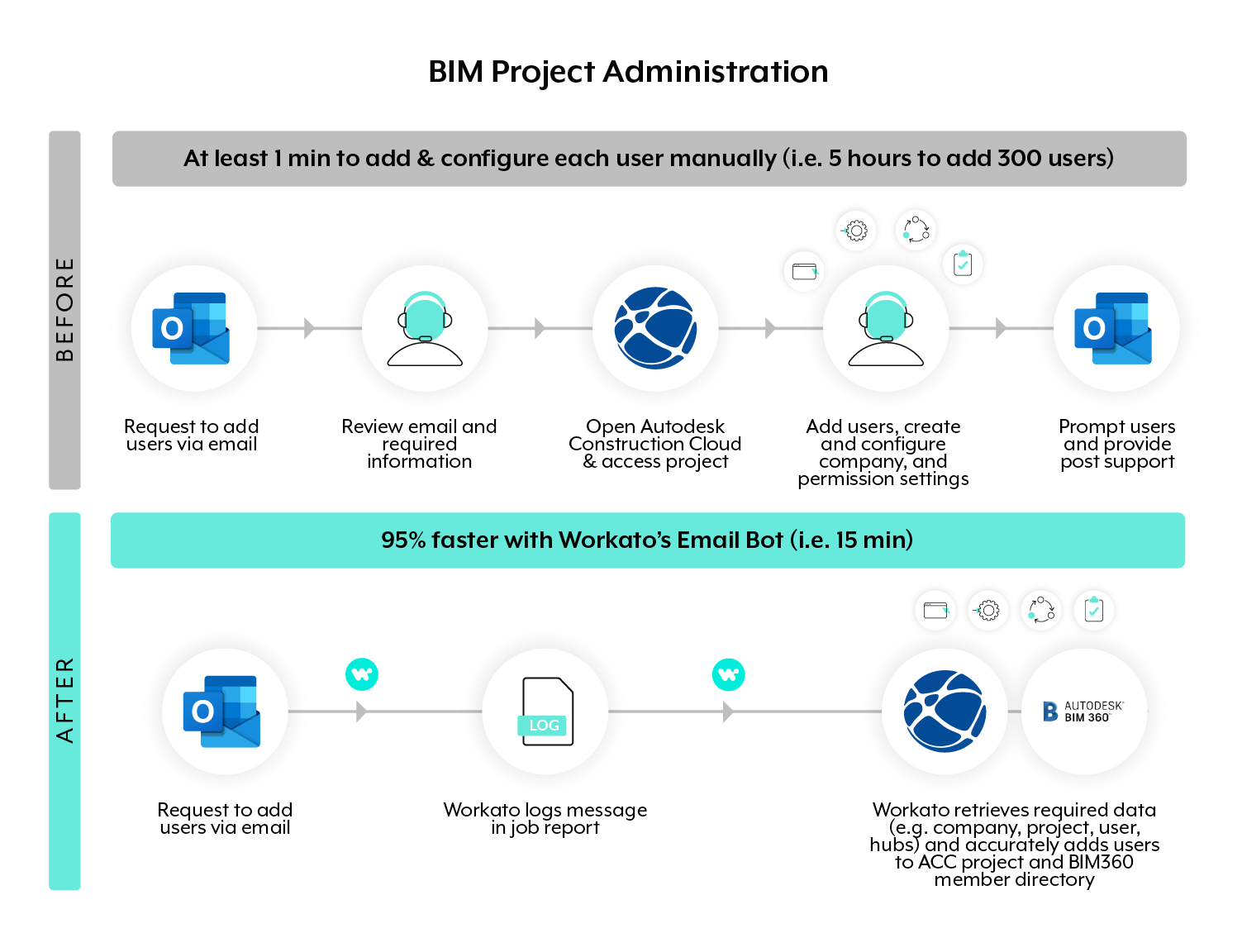

2.) Email bot accelerates BIM project administration

Dom proudly also unveils how he partnered with Autonomation to build and launch an email bot that uses Workato to reimagine project administration for Digital Engineers (also known as Building Information Modelling (BIM) professionals).

With Workato’s powerful recipes, ICON could rebuild their Autodesk library and build functionalities that would have taken several weeks to code out manually.

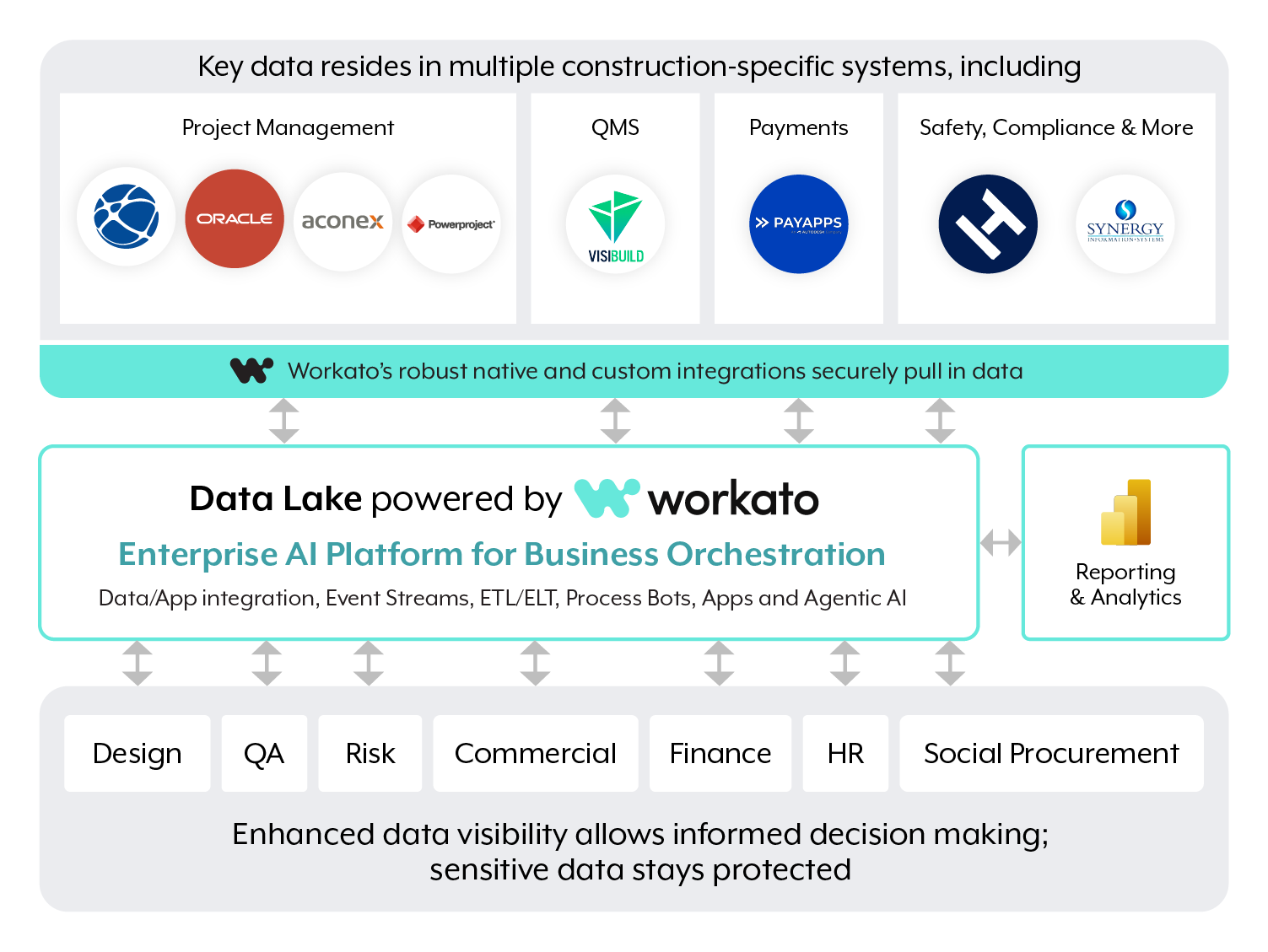

3.) Workato-powered data lake provides visibility with governance

Dom did not just stop at shaving off hours of work for ICON’s engineers. He knew it was time to completely reimagine how ICON orchestrates data across all tools and teams.

By using Workato to pull information into a data lake, ICON is now able to channel streams of critical data to core teams, empowering them to make informed decisions swiftly. Teams not only gain visibility into quality data, but are also able to lock down sensitive data – such as financial data – to specific individuals or departments, in order to prevent these from getting into the wrong hands. Dom also connects PowerBI to this data lake, so that ICON can pull out accurate monthly reports and project reports. This is what that looks like:

Achieving more with less

Here’s what ICON achieved with Workato:

- Zero touch data sync: Multiple thousand PDF drawings are automatically and accurately pulled into ACC from Oracle Aconex, freeing up time for one full graduate hire, while ensuring that drawings are always up-to-date when engineers are onsite.

- 95% faster BIM project administration with Email Bot: This means that 300 users can be added to an Autodesk Construction Cloud (ACC) project within 15 minutes, instead of 5 hours.

- 30x more optimised team size: By automating with Workato, ICON only requires 2 Digital Engineers to deliver on the kind of work being done by 60 digital engineers in other construction firms, such as Dom’s former employer, John Holland Group.

- Improved data visibility: Enhanced data visibility across different platforms, while securely safeguarding sensitive data, has empowered teams to collaborate more freely and get better at making informed decisions swiftly.

- Full product utilisation: ICON is now able to unlock the full value of existing tools, instead of relying on multiple products for unique scenarios. This simplifies workflows and reduces complexity.

With results like these, Dom is being inundated with requests from across the business, including from ICON’s parent company, Kajima.

Laying the foundation for AI innovation

Dom is far from done. In fact, he’s been building up to this moment, where quality data and end-to-end orchestration provide a foundation for innovating with AI.

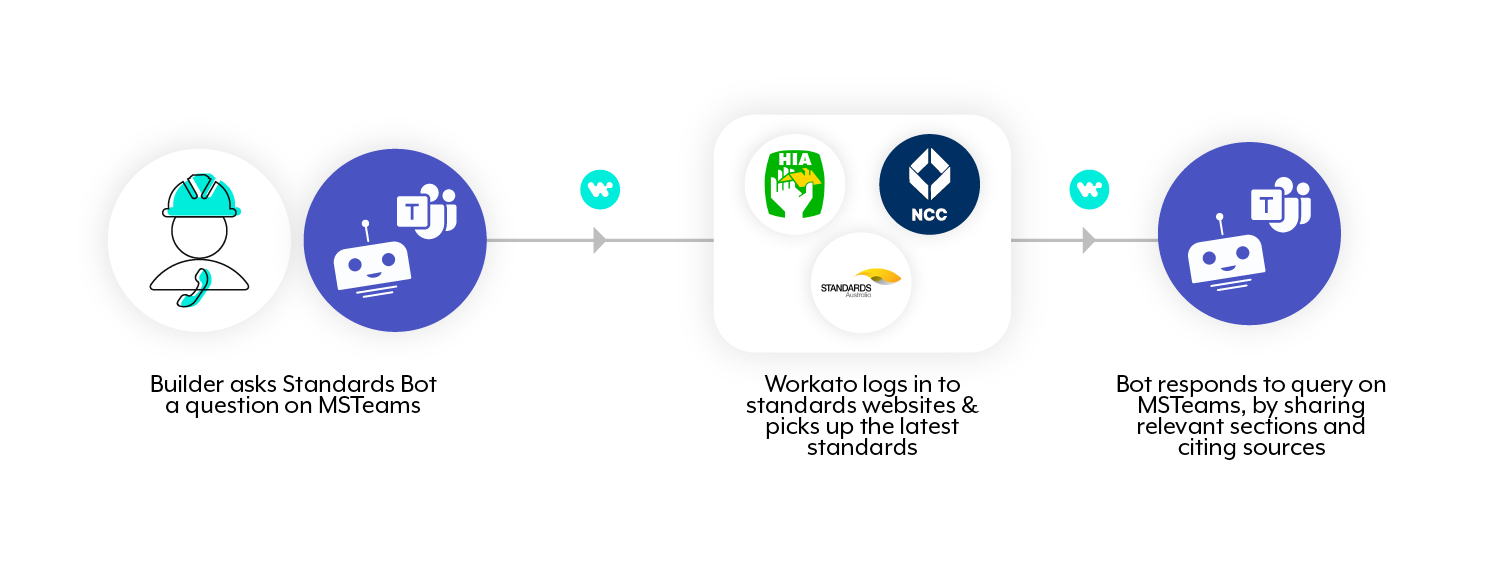

He has begun experimenting with a powerful suite of AI-powered chatbots that will catapult ICON to far greater heights than their competitors. This includes a chatbot that intelligently reviews design changes and another that democratises access to the latest construction standards, which often sits behind paywalls on multiple websites. Here’s a sneak preview of how Standards Bot works:

By combining Workato with AI, Standards Bot scales to work with high volumes of data, unlike other AI tools, and is integrated to live within ICON’s preferred communication tool (MSTeams), swiftly providing critical data on the go.

While Dom does give us this glimpse, he is careful not to spill the beans on his pioneering AI strategy. What we do know is that ICON will be pushing the boundaries of what is possible in construction, hand in hand with Workato.